Label Inspection System with Automatic Rejection

A company manufacturing blow-molded containers for a multinational oil concern was asked to check and confirm the quality of the stickers before delivery. The following parameters were required to be checked: • Presence of stickers on both sides • Front Label Product Name • Front Label Viscosity Grade • Front Label Pack Size • Back Label Product Name • Back Label Barcode / QR Code • Back Label Pack Size • Back Label Coding Area Height • Back Label Coding Area Alignment Any bottle failing any of the above checks was to be rejected off the line. We offered our customized VisiTec-720i Label Inspection and Rejection System for this application. The system was successfully synchronized with the labeling machine’s control system for optimum performance. The system comprised two high-resolution cameras with application-specific inspection software to cater to all the above inspection criteria.

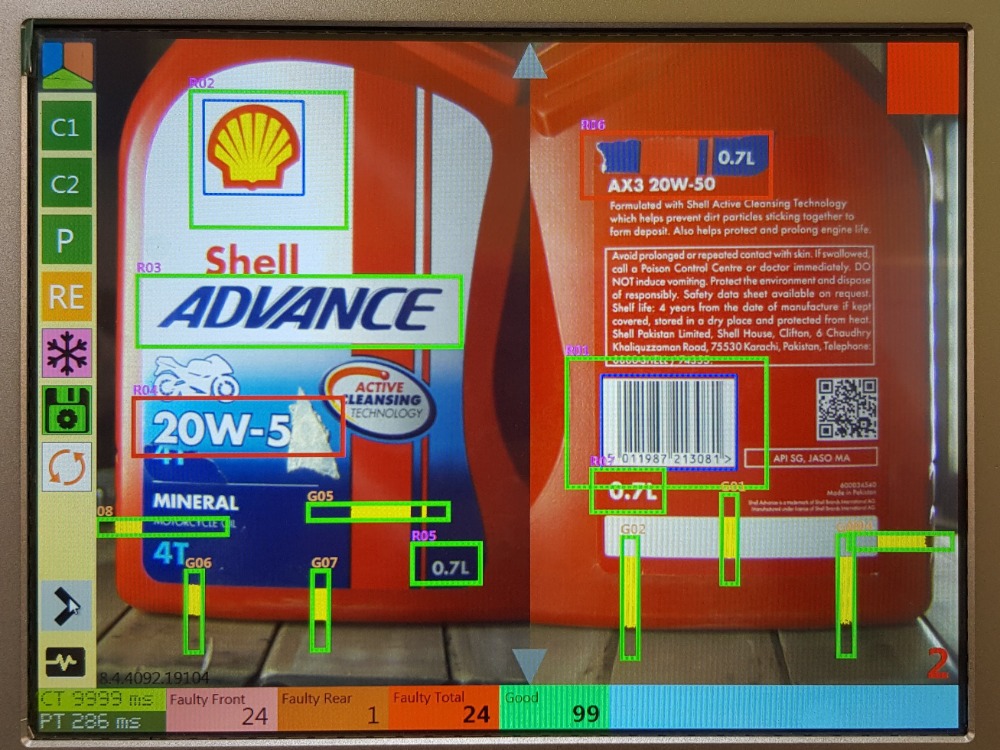

Back-label camera inspection station after installation