Uhlmann Blister Machine Control System Retrofitting

One of our pharmaceutical manufacturer clients was having difficulties maintaining their Uhlmann blister machine. Its control system comprised proprietary cards that the OEM no longer supported. Repairing and troubleshooting these boards was a nightmare.

We proposed them to replace the outdated control system with Siemens S7-1200 PLC-based control system along with touchscreen HMI and rotary encoder for capturing main shaft timing information. The retrofitting procedure was completed successfully with the following benefits:

Operational Advantages:

• Lower downtimes due to more reliable and robust PLC modules as compared to legacy relay / card-based control system

• Inching, Single Cycle, and Continuous operation modes

• Always stop at the preset degree (except in inching mode)

• Remembers position after power interruption

• Variable speed operation thru VFD (password protected)

• Power-efficient design

• Interlocking with temperature controllers for better forming and sealing quality

• Interlocking with all machine door switches for enhanced operational safety

• Report operating data and productivity information in real-time

• Multiple password levels for data protection and individual user accounts

Diagnostics & Troubleshooting Advantages

• Alarms and errors with descriptive text

• Watchdog timers and alarms display

• Editable software cams and delay timers for convenient process adjustments

• Bypass option for certain interlockings for troubleshooting purposes

• Neat panel wiring layout, easy to maintain and trace

• Prolonged machine’s service life thanks to the latest PLC components and a supply of spare parts guaranteed for the future

• Troubleshoot problems quickly with detailed diagnostic information

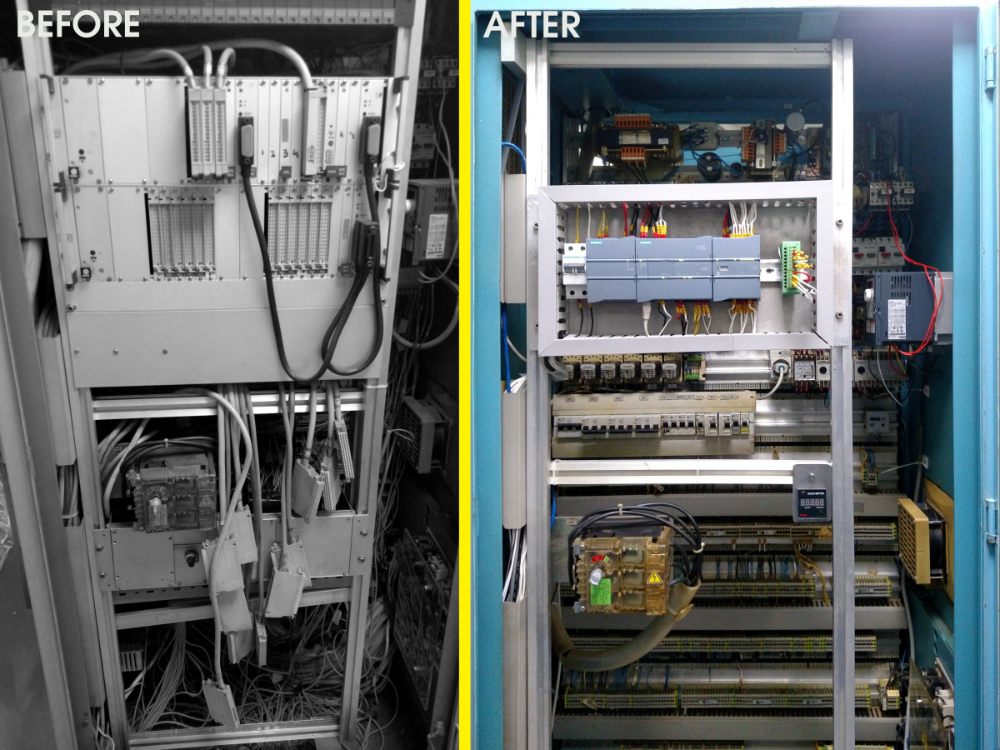

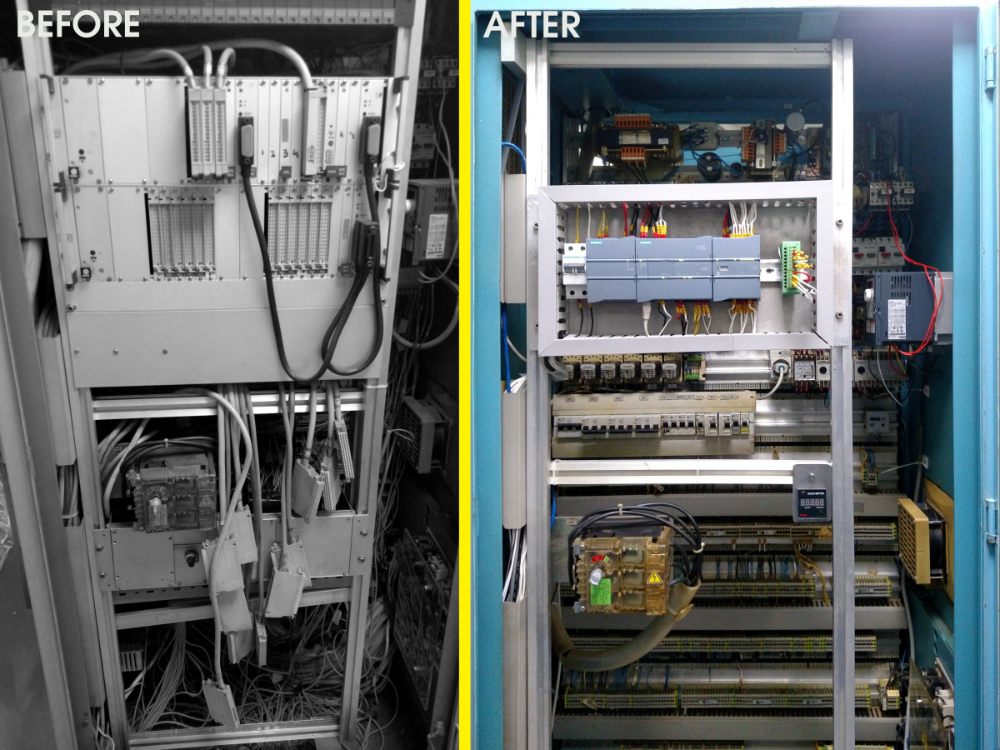

PLC Control Panel

PLC Windows View

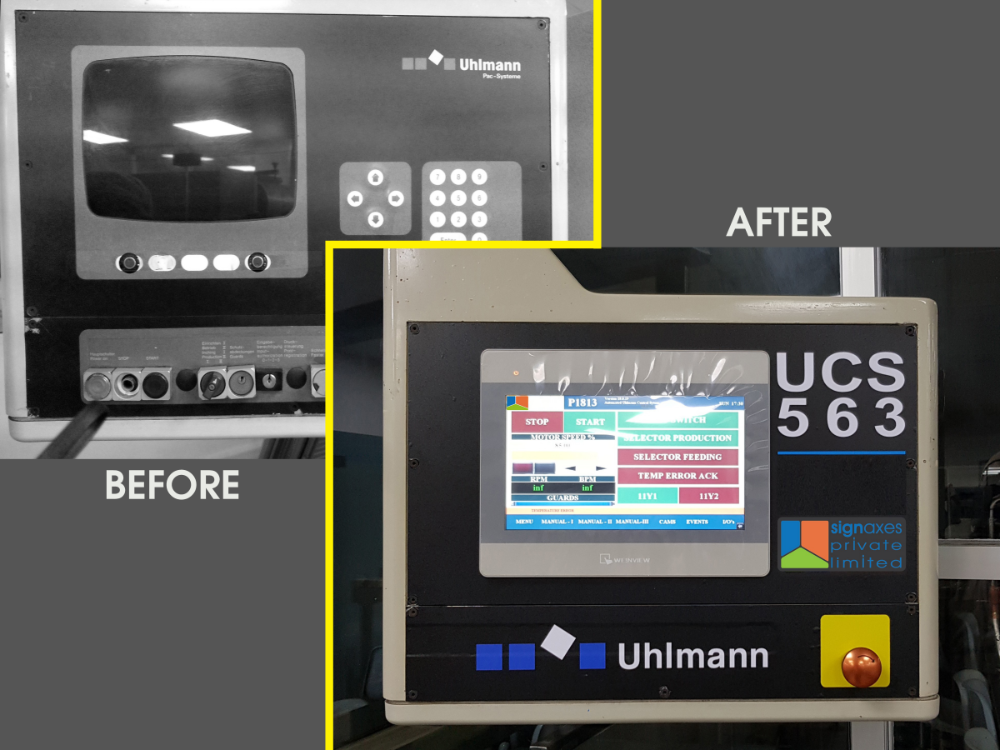

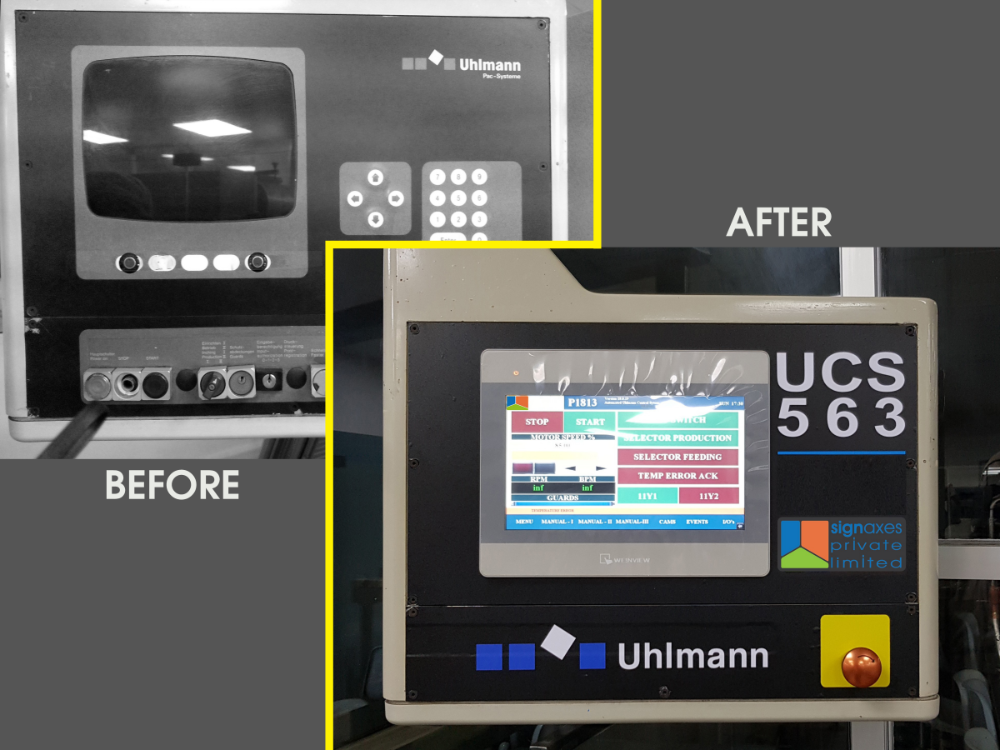

HMI for Machine Operation